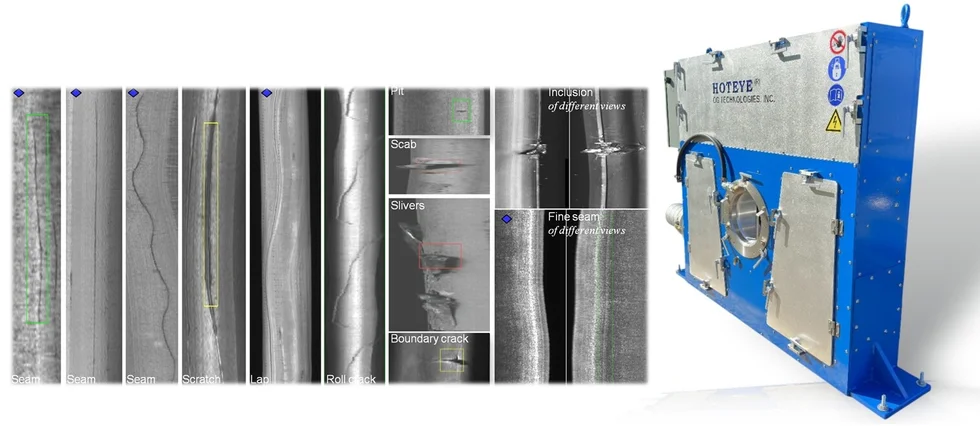

HotEye® / PRii™

From hot rolling (HotEye®) to cold processing (PRii™), OGT's patented opitcal design and proprietary algorithms serve the surface inspection needs meeting the highest quality requirements for bars, rods, wires, pipes, billets and sections.

With high definition 2D imaging, capable of detecting seam cracks as fine as 0.025 mm in surface opening at 110 m/s moving speed for long products of different reflectivity, from dull to mirror like.

Various models for long products from 4 to 300 mm.

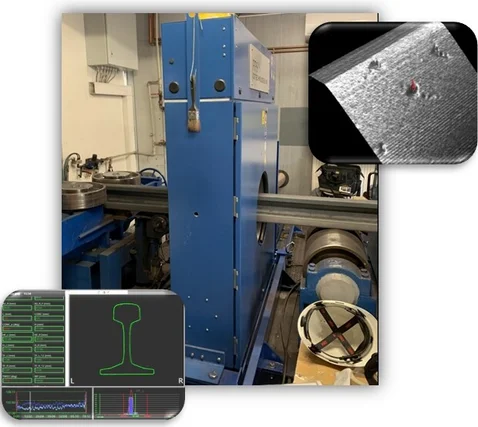

PPS™

By high accuracy and high speed 3D scan, the Planar Profiling System (PPS™) is designed to measure the cross-section profiles for dimensions and geometric properties, and to detect defects on the surface contour formed by the 3D data cloud.

Various models available for different long products, from continuously cast billets to hot rolled billets and bars, hot or cold. Specially developed mathematical models for accurately measuring rails.